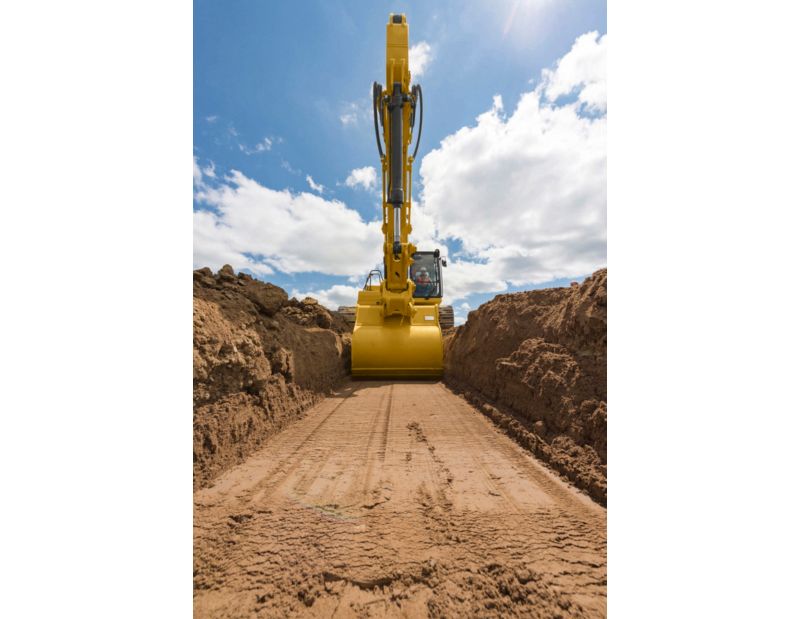

The Cat® 323 delivers power, speed, and high production performance. With more standard technology than previous models, plus reduced fuel and maintenance costs, the Cat 323 has all you need to take your business to the next level.

Caterpillar

323 Hydraulic Excavator

Overview

Photos

Videos

360° View

Exterior

360° exterior view. Double click on the image to zoom in on any area of the product.

Interior

360° interior view. Double click on the image to zoom in on any area of the product.

Showroom

Virtual Product Tour. Double click on the hotspots to see in on any area of the product.

Documents

- 323 (07H) Hydraulic Excavator - Product Brochure (Aus-NZ, Chile, Colombia, Europe, N Am,Türkiye)

- 323 (07H) Hydraulic Excavator - Technical Specifications (Aus-NZ)

- 323 (07H) Hydraulic Excavator - Technical Specifications (N Am)

- 323 (07H) Hydraulic Excavator - Technical Specifications (Europe)

- 323 (07H) Hydraulic Excavator - Technical Specifications (Chile, Colombia,Türkiye)

- Super Long Reach and Long Reach Excavation - Product Brochure (Europe, N Am)

Features

Specifications

-

Engine

Spec Value Net Power - ISO 9249 172 hp Net Power - ISO 9249 (DIN) 175 hp (metric) Engine Model Cat® C7.1 Engine Power - ISO 14396 174 hp Engine Power - ISO 14396 (DIN) 176 hp (metric) Bore 4 in Stroke 5 in Displacement 428 in³ Biodiesel Capability Up to B20¹ Emissions Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards. Note (1) Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 2,200 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture. Note (2) ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. -

Hydraulic System

Spec Value Main System - Maximum Flow 429 l/min (113 gal/min) Maximum Pressure - Equipment 5075 psi Maximum Pressure - Equipment - Lift Mode 5510 psi Maximum Pressure - Travel 4974 psi Maximum Pressure - Swing 3988 psi -

Swing Mechanism

Spec Value Swing Speed 11.25 r/min Note (1) For CE-marked machine default value may be set lower. Maximum Swing Torque 60300 lbf·ft -

Weights

Spec Value Operating Weight 55100 lb Note Long undercarriage, Reach boom, R2.9 (9'6"), Reach stick, Heavy Duty (HD) 1.38 m³ (1.81 yd³) bucket, 790 mm (31") HD triple grouser track shoes and 5,400 kg (11,900 lb) counterweight. -

Service Refill Capacities

Spec Value Fuel Tank Capacity 86.6 gal (US) Cooling System 6.6 gal (US) Engine Oil 6.6 gal (US) Swing Drive 1.6 gal (US) Final Drive - Each 1.3 gal (US) Hydraulic System - Including Tank 61.8 gal (US) Hydraulic Tank 30.4 gal (US) DEF Tank 10.8 gal (US) -

Dimensions

Spec Value Boom Reach 5.7 m (18'8") Stick Reach 2.9 m (9'6") Bucket HD 1.30 m³ (1.71 yd³) Shipping Height - Top of Cab 9.7 ft Handrail Height 9.7 ft Shipping Length 31.3 ft Tail Swing Radius 9.3 ft Counterweight Clearance 3.4 ft Ground Clearance 1.5 ft Track Length 14.6 ft Length to Center of Rollers 12 ft Track Gauge 7.8 ft Transport Width 10.4 ft -

Working Ranges and Forces

Spec Value Maximum Digging Depth 22.1 ft Boom Reach 5.7 m (18'8") Stick Reach 2.9 m (9'6") Bucket HD 1.30 m³ (1.71 yd³) Maximum Reach at Ground Level 32.4 ft Maximum Cutting Height 31 ft Maximum Loading Height 21.3 ft Minimum Loading Height 7.1 ft Maximum Depth Cut for 2440 mm (8 ft) Level Bottom 21.5 ft Maximum Vertical Wall Digging Depth 18.8 ft Bucket Digging Force - ISO 34308 lbf Stick Digging Force - ISO 26094 lbf -

Air Conditioning System

Spec Value Air Conditioning The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 0.85 kg (1.9 lb) of refrigerant which has a CO2 equivalent of 1.216 metric tonnes (1.340 tons).

Standard Equipment

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

CAB

- Rollover Protective Structure (ROPS)

- Air-adjustable seat with heat (Deluxe only)

- Auto-adjustable seat with heat and air ventilation (Premium only)

- High-resolution 254 mm (10 in) LCD touchscreen monitor

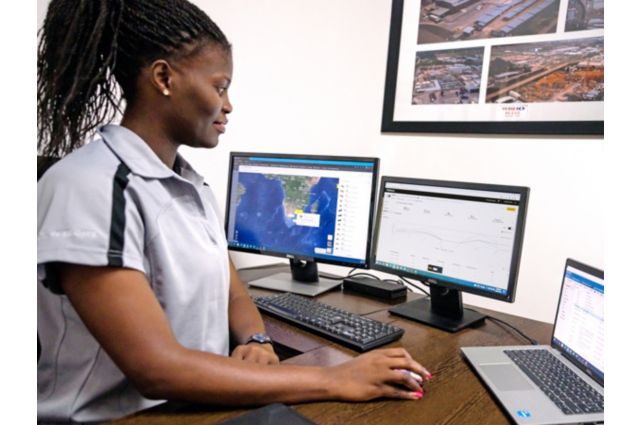

CAT TECHNOLOGY

- VisionLink®

- Remote Flash

- Remote Troubleshoot

- Work tool recognition and tracking (PL161)

- Cat Grade with 2D

- Cat Assist

- Cat Payload

ELECTRICAL SYSTEM

- Two 1,000 CCA maintenance-free batteries

- Programmable time-delay LED working lights

- LED chassis light, left-hand/right-hand boom lights, cab lights

ENGINE

- Cat 7.1 single turbo diesel engine

- Three selectable power modes

- Automatic engine speed control

- 46°C (115°F) high-ambient cooling capacity (Europe only)

- 52°C (125°F) high-ambient cooling capacity

- -18°C (0°F) cold start capability

- Double element air filter with integrated precleaner

- Reversing electric cooling fans

HYDRAULIC SYSTEM

- Boom and stick regeneration circuits

- Auto hydraulic warm up

- Auto two-speed travel

- Boom and stick drift reduction valve

- Auto dig boost

- Auto heavy lift

SAFETY AND SECURITY

- 2D E-Fence

- Auto hammer stop

- Rearview camera

- Right-side-view camera

- Lockable disconnect switch

- Ground-level engine shutoff switch

- Right-hand handrail and handhold

- Signaling/warning horn

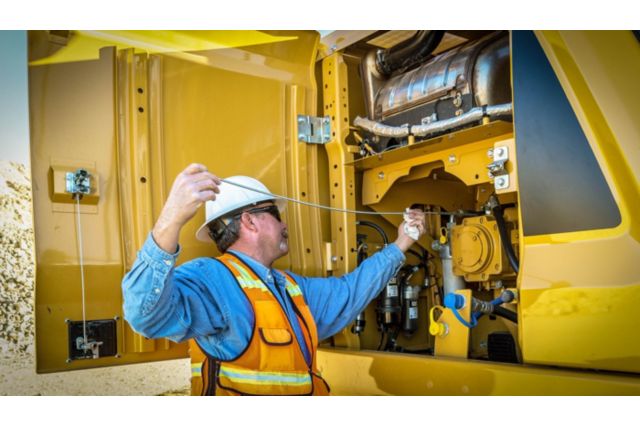

SERVICE AND MAINTENANCE

- Sampling ports for Scheduled Oil Sampling (S·O·S℠)

- Ground-level and platform-level engine oil dipsticks

- Integrated vehicle health management system

UNDERCARRIAGE AND STRUCTURES

- Long undercarriage

- Tie-down points on base frame

Optional Equipment

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

BOOMS AND STICKS

- 5.7 m (18'8") Reach boom

- 5.7 m (18'8") HD Reach boom

- 2.7 m (8'10") stub + 3.3 m (10'10") fore, Variable Angle boom

- 8.85 m (29'0") Super Long Reach boom

- 2.5 m (8'2") Reach stick

- 2.9 m (9'6") Reach stick

- 2.5 m (8'2") HD Reach stick

- 2.9 m (9'6") HD Reach stick

- 3.9 m (12'10") Reach stick

- 2.9 m (9'6") HD Thumb Ready Reach stick

- 6.28 m (20'7") Super Long Reach stick

CAB

- Operator Protective Guards (OPG)

- Cat Stick Steer

CAT TECHNOLOGY

- VisionLink Productivity

- Operator Coaching

- Cat Grade with 2D with Attachment Ready Option (ARO)

- Cat Grade with 3D (single or dual GNSS)

- Cat Grade 3D Ready

- Cat Grade Connectivity

- Cat Advanced Payload

- Cat Tiltrotator (TRS) integration

ENGINE

- -32°C (-25°F) cold start capability

HYDRAULIC SYSTEM

- Boom and stick lowering check valves

- SmartBoom™ (Europe only)

- Hammer return filter circuit

- Advanced tool control (two pump, one/two way high-pressure flow)

- Hydraulic efficiency monitoring

- Medium-pressure circuit

- Quick coupler circuit for Cat Pin Grabber

SAFETY AND SECURITY

- Cat Command (remote control)

- 360° visibility

- Inspection lighting

UNDERCARRIAGE AND STRUCTURES

- 600 mm (24") single grouser shoes

- 600 mm (24") HD double grouser shoes

- 600 mm (24") HD triple grouser shoes

- 700 mm (28") HD triple grouser shoes

- 790 mm (31") HD triple grouser shoes

- 900 mm (35") HD triple grouser shoes

Sign up for Ziegler CAT emails

Events, updates, and offers

H130 GC S

H130 GC S

H120 GC S

H120 GC S

H115 GC S

H115 GC S

H115 S

H115 S

H120 S

H120 S

H130 S

H130 S

P224 Secondary Pulverizer

P224 Secondary Pulverizer

MP324 Demolition Jaw

MP324 Demolition Jaw

MP318 Demolition Jaw

MP318 Demolition Jaw

MP324 Universal Jaw

MP324 Universal Jaw

MP318 Universal Jaw

MP318 Universal Jaw

MP324 Pulverizer Jaw

MP324 Pulverizer Jaw

MP318 Pulverizer Jaw

MP318 Pulverizer Jaw

CVP75

CVP75

CVP110

CVP110

MP324 Concrete Cutter Jaw

MP324 Concrete Cutter Jaw

MP324 Shear Jaw

MP324 Shear Jaw

MP318 Shear Jaw

MP318 Shear Jaw

MP324 Tank Shear

MP324 Tank Shear