No matter how hard the work, the Cat® 374 Excavator is built to do it. Three modes of operation, Power, Smart, and Eco, help operators reduce fuel consumption and optimize performance. Built for durability, the 374 is structurally sound with reinforced track rollers, booms, sticks, upper and lower frames. Simple, easy-to-use onboard technology such as Cat Payload, Cat Grade with 2D, Lift Assist, 2D E-Fence, and Work Tool Recognition helps boost efficiency and jobsite safety. The deluxe and standard cab options feature operator-pleasing ergonomic amenities such as the front-facing control panel, keyless pushbutton start, and large touchscreen monitor with jog dial keys.

Cat

Cat® 374 Hydraulic Excavator

Overview

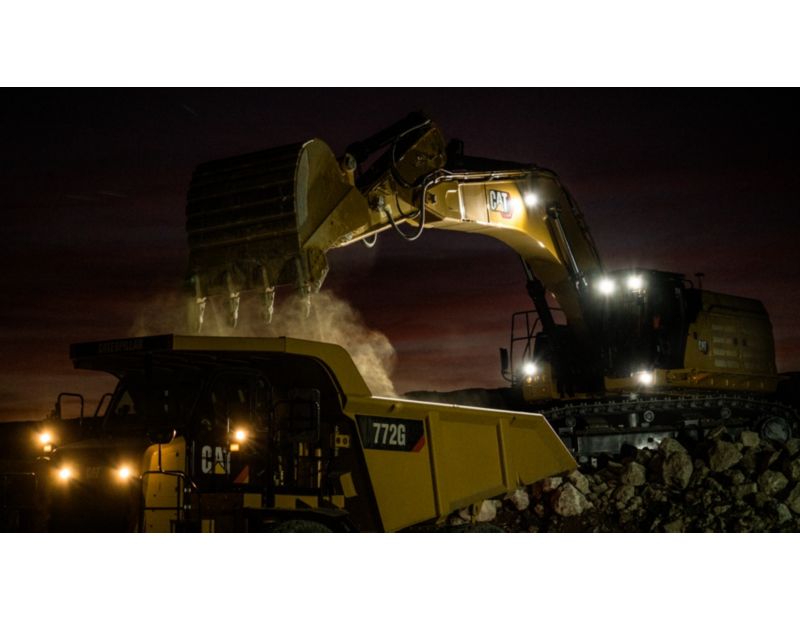

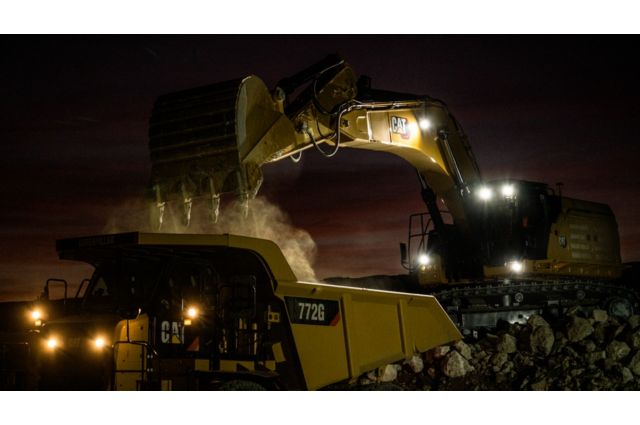

Photos

Videos

360° View

Exterior

360° Exterior view. Double click on the image to zoom in on any area of the product. Exterior (HTML) 01 Hotspot 01

Interior

360° Interior view. Double click on the image to zoom in on any area of the product.

Showroom

Virtual Product Tour. Double click on the hotspots to see in on any area of the product.

Documents

- 374 (07H) Hydraulic Excavator - Product Brochure (Aus-NZ, Chile, Europe, N Am, S Korea, Türkiye)

- 374 (07H) Hydraulic Excavator - Key Features (Japan)

- 374 (07H) Hydraulic Excavator - Technical Specifications (Aus-NZ, Chile, Colombia, N Am, S Korea, Türkiye)

- 374 (07H) Hydraulic Excavator - Technical Specifications (Europe)

- 374 (07H) Hydraulic Excavator - Technical Specifications (Japan)

- Payload Technologies for Excavators

Features

Specifications

-

Engine

Spec Value Net Power - ISO 9249 484 hp Net Power - ISO 9249 (DIN) 491 hp (metric) Engine Model Cat C15 Engine Power - ISO 14396 485 hp Engine Power - ISO 14396 (DIN) 492 hp (metric) Bore 5.4 in Stroke 6.7 in Displacement 928 in³ Biodiesel Capability Up to B20¹ Emissions Meets U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, and Japan 2014 emission standards. Note (1) Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 1,700 rpm. Advertised power is tested per the specified standard in effect at time of manufacture. Note (2) ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels.Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. -

Hydraulic System

Spec Value Main System - Maximum Flow - Implement 237 gal/min Maximum Pressure - Equipment 5366 psi Maximum Pressure - Equipment - Lift Mode 5511 psi Maximum Pressure - Travel 5076 psi Maximum Pressure - Swing 5076 psi -

Swing Mechanism

Spec Value Maximum Swing Torque 220000 lbf·ft Note (1) *For CE-marked machine default value may be set lower -

Weights

Spec Value Operating Weight 162900 lb Note Long Variable Gauge undercarriage, Reach boom, R4.67VB (15'4") stick, SD 3.3 m³ (4.32 yd³) bucket, 900 mm (35") HD double grouser shoes and removal type counterweight. -

Service Refill Capacities

Spec Value Fuel Tank Capacity 243 gal (US) Cooling System 19 gal (US) Engine Oil 16 gal (US) Swing Drive 5 gal (US) Final Drive - Each 9 gal (US) Hydraulic System - Including Tank 164 gal (US) Hydraulic Tank 86 gal (US) DEF Tank 21 gal (US) -

Dimensions

Spec Value Boom Reach 7.8m (25'7") Stick R3.6m (11'10") Bucket SD 3.3 m³ (4.32 yd³) Shipping Height - Top of Cab 11.8 ft Handrail Height 13 ft Shipping Length 44.9 ft Tail Swing Radius 13.8 ft Counterweight Clearance 4.1 ft Ground Clearance 2.6 ft Track Length 19.3 ft Track Length to Center of Rollers 15.5 ft Track Gauge 11.2 ft Transport Width 11.1 ft Note Track gauge undercarriage extended with 650 mm (26") shoes; transport width undercarriage retracted with 650 mm (26") shoes and no steps -

Working Ranges and Forces

Spec Value Maximum Digging Depth 28.1 ft Boom Reach 7.8m (25'7") Stick R3.6m (11'10") Bucket SD 3.3 m³ (4.32 yd³) Maximum Reach at Ground Level 43.2 ft Maximum Cutting Height 41.2 ft Maximum Loading Height 27.7 ft Minimum Loading Height 10.1 ft Maximum Depth Cut for 2440 mm (8 ft) Level Bottom 27.8 ft Maximum Vertical Wall Digging Depth 22.8 ft Bucket Digging Force - ISO 80550 lbf·ft Stick Digging Force - ISO 66390 lbf·ft -

Air Conditioning System

Spec Value Air Conditioning The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.00 kg (2.2lb) of refrigerant, which has a CO2 equivalent of 1.430 metric tonnes (1.576 tons).

Standard Equipment

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

CAB

- High-resolution 254 mm (10") LCD touch screen monitor

- Heated seat with air-adjustable suspension (Deluxe only)

- Heated and cooled seat with auto adjustable suspension (Premium only)

- Sound suppressed cab with viscous mounts

- Automatic bi-level air conditioner

- Jog dial and shortcut keys for monitor control

- Keyless push-to-start engine control

- Height-adjustable console, infinite with no tool

- Tilt-up left-side console

- 51 mm (2") orange seat belt

- Bluetooth integrated radio (including USB, aux port and microphone)

- 2 x 12V DC outlets

- Document storage

- Rear head storage net and lunchbox storage net

- Cup and bottle holders

- Openable two-piece front window

- Upper radial wiper with washer

- Parallel wiper with washer (Premium only)

- Openable polycarbonate skylight hatch (Premium only)

- LED dome light

- Floor welcome light

- Roller front sunscreen

- Roller rear sunscreen (Premium standard)

- Rear window emergency exit

- Washable floor mat

- Beacon Ready

CAT TECHNOLOGY

- VisionLink®

- Remote Flash

- Remote Troubleshoot

- Operator Coaching

- Compatibility with radios and base stations from Trimble, Topcon, and Leica

- Capability with 3D grade systems from Trimble, Topcon, and Leica

- Cat® Grade with 2D

- Cat® Assist (Grade, Boom, Bucket, Swing, Lift)

- Cat® Payload (On-the-go weighing, Semiautomatic calibration, Payload/cycle information, USB Reporting Capability)

- Work tool recognition and tracking (Requires PL161 attachment locator on work tool and Bluetooth receiver on machine)

ELECTRICAL SYSTEM

- Maintenance-free 1,400 CCA batteries (x2)

- Centralized electrical disconnect switch

- Chassis light

- Exterior lights (integrated into storage box)

ENGINE

- Three selectable modes: Power, Smart, and Eco

- Auto engine speed control

- Up to 4500m (14,760 ft) altitude capability

- 52°C (126°F) high-ambient cooling capacity

- -18°C (-0.4°F) cold start capability

- Hydraulic reverse fan

- Double element air filter with integrated pre-cleaner

- 3 vertical side-by-side cooling system

- 95 Amp alternator

HYDRAULIC SYSTEM

- Boom and stick regeneration circuit

- Electronic main control valve

- Dedicated closed loop swing circuit

- Auto heavy lift

- Auto hydraulic oil warmup

- Auto swing parking brake

- High performance hydraulic return filter

- Two speed travel

- Bio hydraulic oil capability

SAFETY AND SECURITY

- Caterpillar One Key security system

- Lockable external tool / storage box

- Lockable door, fuel, and hydraulic tank locks

- Lockable disconnect switch

- Service platform with anti-skid plate & recessed bolts

- Right hand handrail and hand hold (ISO 2867:2011 compliant)

- Visibility mirror package

- Signaling/warning horn

- Ground-level secondary engine shutoff switch

- Rearview and right-hand-sideview cameras

- Walkway

- Travel alarm (North America only)

- 2D E-Fence (E-ceiling, E-floor, E-swing, E-wall, E-cab avoidance)

- Auto hammer stop

SERVICE AND MAINTENANCE

- Integrated vehicle health management system

- Auto lube ready

- Grouped location of engine oil & fuel filters

- Sampling ports for Scheduled Oil Sampling (S·O·S℠)

- QuickEvac maintenance ready

UNDERCARRIAGE AND STRUCTURES

- Long variable gauge undercarriage

- Swivel guard

- Grease lubricated track

- Standard counterweight

- HD bottom guard

- HD travel motor guard

- HD travel motor guard

Optional Equipment

NOTE

- Standard and optional equipment may vary. Consult your Cat® dealer for details.

BOOMS AND STICKS

- 7.0m (23') Mass boom

- 7.8m (25'7") Reach boom

- 2.57m (8'5") Mass stick

- 2.84m (9'4") Reach stick

- 3.0m (9'10") Mass stick

- 3.6m (11'10") Reach stick

- 4.15m (15'4") Reach stick

- 4.67m (15'4") Reach stick

- Bucket Linkage, VB family with lifting eye, Cat® Grade

- Bucket Linkage, VB family without lifting eye, Cat® Grade

- Bucket Linkage, WB family with lifting eye, Cat® Grade

- Bucket Linkage, WB family without lifting eye, Cat® Grade

CAB

- Cat® Stick Steer

- Auxiliary relay

- Additional high-resolution LCD touch screen monitor for Cat® Grade Advanced 2D and 3D

- Roller rear sunscreen (Deluxe)

- Radial lower wiper

- Joystick with horizontal sliders

- LH/RH electrical pedal for tool control

- Dual exit rear window kit

- Front windshield laminated glass (P5A glass, EU demolition regulation)

- Cab/Operator Protective Guards (OPG) (not compatible with cab light cover, rain protector)

- Mesh guard full front (not compatible with cab light, cover, rain protector)

- Mesh guard lower half front

- Rain protector for front windshield plus cab light cover

- Full protecting vandalism guard

CAT TECHNOLOGY

- VisionLink® Productivity

- VisionLink® Productivity back office reporting

- Cat® Grade Connectivity

- Cat® Grade 2D with Attachment Ready Option (ARO)

- Cat® Grade with 3D (single or dual GNSS)

- Cat® Grade 3D Ready

- GNSS antennae

- Laser catcher

- Cat® Tilt Rotator (TRS) Integration

- Operator Coaching

- Advanced Payload (Daily totals, Custom lists, Smart weight target, E-ticket Integration)

ELECTRICAL SYSTEM

- 1,800 lumen LED premium surround lights

- LED boom and cab lights

ENGINE

- -32°C (-25°F) cold start capability

- Cold start block heaters

HYDRAULIC SYSTEM

- Hydraulic efficiency monitoring

- Advanced tool control

- Medium-pressure auxiliary circuit

- Quick coupler circuit

SAFETY AND SECURITY

- Travel alarm

- Swing alarm

- 360° visibility

- Boom lowering check valve

- Stick lowering check valve

- Inspection lighting

- Tilt-up walkway

- Bluetooth key fob

- 76mm (3") retractable seat belt

SERVICE AND MAINTENANCE

- Electric refueling pump with auto shutoff

UNDERCARRIAGE AND STRUCTURES

- Three-piece segmented track guiding guards

- Two-piece segmented track guiding guards

- Counterweight with removal device

- 650mm (26") HD double grouser track shoes

- 750mm (30") HD double grouser track shoes

- 900mm (35") HD double grouser track shoes

Sign up for Ziegler CAT emails

Events, updates, and offers

CW70

CW70

H190 S

H190 S

H215 S

H215 S

H180 S

H180 S

MP365 Demolition Jaw

MP365 Demolition Jaw

MP365 Pulverizer Jaw

MP365 Pulverizer Jaw

S3070 Rotating Scrap & Demolition Shear

S3070 Rotating Scrap & Demolition Shear

MP365 Concrete Cutter Jaw

MP365 Concrete Cutter Jaw

MP365 Shear Jaw

MP365 Shear Jaw