The Cat® Next Generation D8 Dozer delivers renowned performance you expect, with the added benefit of next generation technology. A fully automatic, 4-speed transmission makes efficient operation easy, without having to manage gear shifts.The broadest range of technology features in the industry works together seamlessly to help you make the most of your equipment investment. Common interface and controls from the D5 through D8 make it easy to operate different machine sizes.

Cat

D8 Dozer

Overview

Photos

Videos

360° View

Exterior

360 Exterior view. Double click on the image to zoom in on any area of the product.

Interior

360 Interior view. Double click on the image to zoom in on any area of the product.

Features

Specifications

-

Engine

Spec Value Engine Model Cat® C15 Power - Net 363 hp Net Power - ISO 9249/SAE J1349 363 hp Net Power - ISO 9249 (DIN) 368 mhp Build Number 22A Emissions U.S. EPA Tier 4 Final/ EU Stage V/Japan 2014/Korea Stage V/China Nonroad Stage IV Note (1) Net power at 2,050 rpm. Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture. Note (2) Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). -

Weights

Spec Value Operating Weight 87083 lb -

Transmission

Spec Value Powertrain Fully Automatic 4-Speed with Lock-up Clutch (LUC) torque divider -

Service Refill Capacities

Spec Value Fuel Tank 165.6 gal (US) DEF Tank 8.7 gal (US) -

Standard SU

Spec Value Operating Weight 87083 lb Ground Pressure 13 psi Width of Standard Shoe 24 in Blade Semi-Universal (SU) Blade Capacity 13.47 yd³ -

LGP

Spec Value Operating Weight 83963 lb Ground Pressure 7.9 psi Width of Standard Shoe 38 in Blade LGP Semi-Universal (SU) Blade Capacity 12.9 yd³ -

Waste Handler

Spec Value Operating Weight 87964 lb Ground Pressure 12.1 psi Width of Standard Shoe 26 in Blade Semi-Universal (SU) Landfill Blade Capacity 27.7 yd³ -

LGP Waste Handler

Spec Value Operating Weight 91591 lb Ground Pressure 8.6 psi Width of Standard Shoe 38 in Blade Semi-Universal (SU) Landfill Blade Capacity 27.7 yd³ -

Sustainability

Spec Value Recyclability 98% -

Air Conditioning System

Spec Value Air Conditioning The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.36 kg of refrigerant which has a CO2 equivalent of 1.946 metric tonnes.

Standard Equipment

NOTE

- Standard and optional equipment may vary. Consult your Cat® dealer for details.

Powertrain

- Cat® C15 Engine

- Fully-automatic 4-speed transmission with lock-up clutch (LUC) torque divider

- Aftercooler, air-to-air (ATAAC)

- Extended life coolant

- Diesel exhaust fluid (DEF) system - electronic fill indicator, heated lines/tank

- Differential steering

- Engine air filter with electronic service indicator

- Engine air precleaner with dust ejection

- Engine idle shutdown

- Final drives, double reduction - Standard or LGP

- Fuel water seperator

- Fuel priming pump, electric

- Fan, hydraulic demand

- Fan, auto reversing

- Radiator, aluminum bar plate with debris resistant cores

- High performance single plane cooling system

- Starting aid, automatic ether

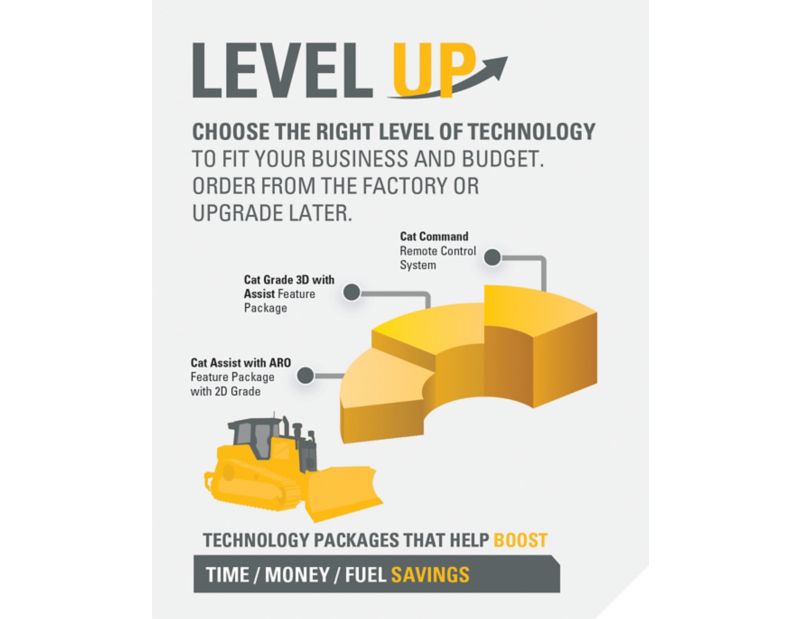

Cat Technology

- Cat Slope Indicate

- Cat Assist with ARO package

- Third party grade control ready cab

- Compatibility with radios and base stations from Trimble, Topcon, and Leica

- Capability to install 3D grade systems from Trimble, Topcon, and Leica

- Product Link™ – Cellular

- Remote Flash/Troubleshoot

- Cat Track Wear Sensor

- Machine security - passcode

- Remote control ready

Operator Environment

- Fully redesigned cab with integrated ROPS and FOPS, single pane door glass, sliding windows, with Cat Advanced Cabin Filtration

- Full-color 254 mm (10 in) liquid crystal touchscreen display

- High definition rear view camera with backup lines

- In-display key machine features

- Operator ID/operator ID with security

- Cloth seat with mechanical adjustable lumbar support

- Armrests adjustable fore-aft and vertically

- Electrohydraulic implement and steering controls

- Joystick control - ARO

- Decelerator pedal

- Fresh air filter

- Cab mounted modular HVAC system with automatic reversing fans. Automatic temperature and blower control with distributed ducting.

- Rearview mirror

- Retractable 76 mm (3 in) seat belt

- Cup holders

- Dash foot pads

- Entertainment radio with Bluetooth and microphone

- Lunch box storage

- Wipers

- USB and AUX ports

- Operator presence switch

Guarding and Screens

- Bottom guards - standard

Electrical

- Lights - 6 LED

- Access/egress lighting with shutdown timer

- Backup alarm

- Converter: 15 Amp, 12V outlets

- Forward warning horn

Hydraulics

- Load sensing hydraulics

- Independent steering and implement pumps

- Dozer tilt hydraulics - single tilt

- Guarded blade hydraulic hoses

- Electronically enabled quick drop valve

- Rear hydraulics ripper and winch ready

Batteries, Starters, Alternators, and Coolant

- 150 Amp alternator

- 24 Volt starter

- Engine coolant, –37° C (–35° F)

- Four maintenance free 12-volt batteries (900 cca) (24-volt system)

Push Arms

- Standard

Undercarriage

- Standard or low ground pressure (LGP) undercarriage

- Heavy duty with positive pin retention (PPR) undercarraige - 44 section track, sealed and lubricated, single grouser shoes

- Suspension-type undercarriage

- Carrier rollers

- Hydraulic track adjusters

- Lifetime lubricated track and roller

- Moderate service track shoes

- Track guide

- Sprocket rim segments, replaceable

- 8-roller tubular track roller frame (carrier roller ready)

- Two-piece master links

Service and Maintenance

- 30-minute cab removal

- Centralized, remote mounted pressure taps

- Ecology drains

- Extended service intervals (500 hours engine, 1,000-hour powertrain)

- Ground level service center (remote electrical disconnect, secondary shutdown switch, hour meter, jump start)

- Heavy duty perforated radiator doors, louvered and hinged

- Under hood work light

- Removable engine enclosures, perforated and hinged

- Scheduled Oil Sampling (S·O·S℠) ports

- Shovel holder

Optional Equipment

Note

- Standard and optional equipment may vary. Consult your Cat® dealer for details

Powertrain

- Brakes, extreme service

- Engine air precleaner with screen and dust ejector

- Engine with thermal shield

- Final drives, double reduction - Arctic, Waste

- Oil change system, high speed

- Sound suppression

- Starting aid, jacket water heater (110V or 220V)

Cat Technology

- Cat Grade 3D Ready with Assist package (hardware only)

- Cat Grade 3D with Assist package

- Product Link™ – dual mode

- Grade connectivity

- Grade corrections radio

- Machine security - Bluetooth

- Cat Command for Dozing

Operator Environment

- High debris cab, fully redesigned with integrated ROPS and FOPS, impact resistant polycarbonate doors, solid side windows for improved sealing, powered precleaner with Cat Advanced Cabin Filtration for improved performance and filter life

- Cab glass capable of withstanding up to 40 psi

- Deluxe leather heated/ventilated seat with electronic adjustable lumbar support

- Powered fresh air filter precleaner

- Communication radio ready

- Floor plate and pedals for shorter operators

- Emergency hammer

- Window shades

Undercarriage

- Heavy duty extended life (HDXL) with PPR undercarriage - 44 section track, sealed and lubricated, single grouser shoes

- Waste undercarriage

- Arctric undercarriage

- Extreme service track shoes

Blades

- Semi-Universal (SU)

- Universal

- Waste/Landfill

- Angle

- Rock guard/wear plate

- Push plate

- FirstCut cutting edges (SU blades)

Push Arms

- Extreme

Hydraulics

- Dozer tilt hydraulics – dual tilt

Electrical

- Premium lights – 12 LED

- Beacon warning light

Batteries, Starters, Alternators and Coolant

- 150 Amp ducted alternator

- Arctic engine coolant, –51° C (–60° F)

Service and Maintenance

- Fast fuel fill

- High-speed oil change

- Heavy duty radiator doors for waste and woodchip applications

- Quick access cab floor

Attachments

- Multi-shank ripper with CapSure ripper tips and shank protector

- Single shank ripper with CapSure ripper tip and shank protector

- Pin puller (single shank)

- Rear striker box with striker bar

- Rear striker bar

- Winch, PV140

- Rear counterweight

- Drawbar

Guarding and Screens

- Bottom guards - heavy duty, powered, sealed

- Cab rear screen - fixed or hinged

- Cab side screens - hinged

- Fuel tank guards

- HVAC guard

- Light guards

- Striker bars, front, suspended

- Sweeps package

Sign up for Ziegler CAT emails

Events, updates, and offers